Computer-Controlled Cutting

Laser Cut

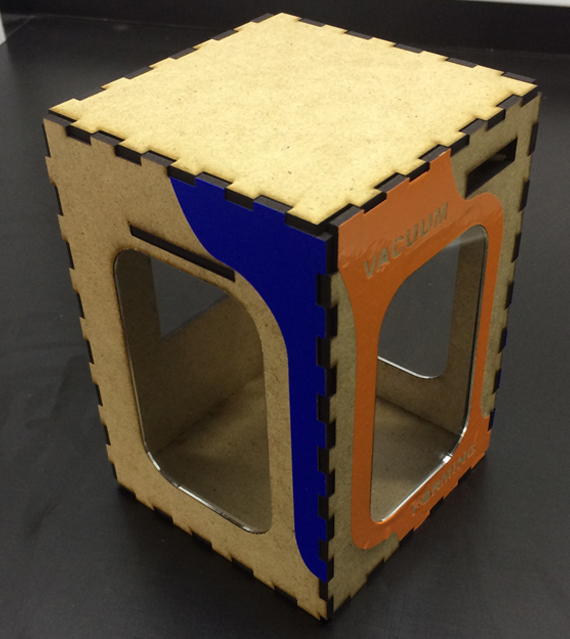

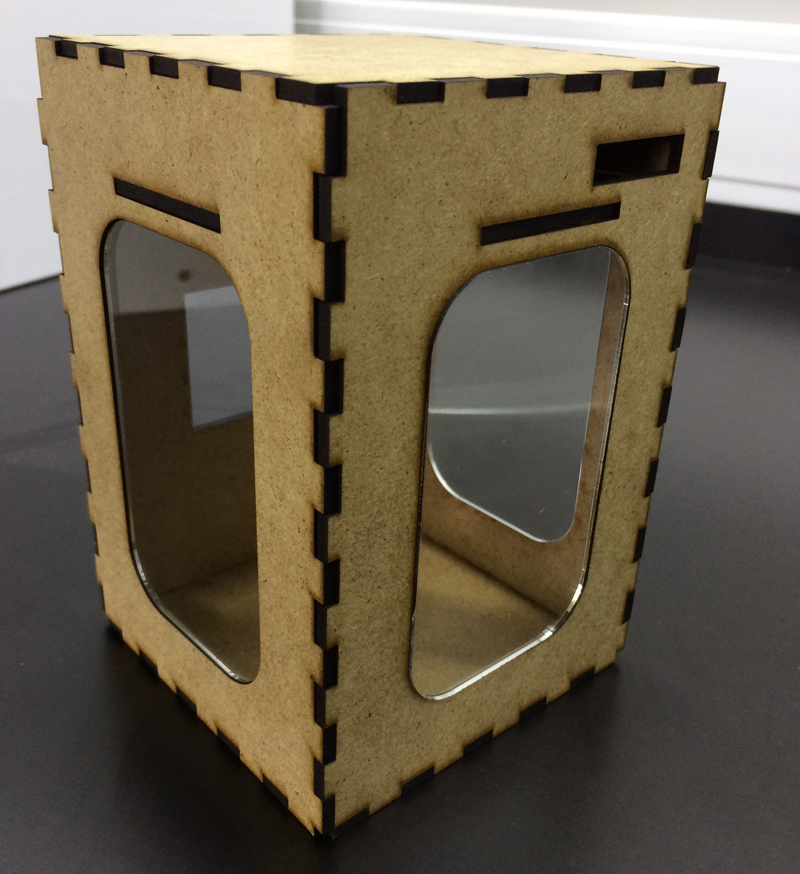

For try to use the laser cut i make a small prototype of my machine vacuum forming. I draw in small scale the main box os my machine, i draw in drawing option in Solidworks. In solidworks i make a Parametric model.

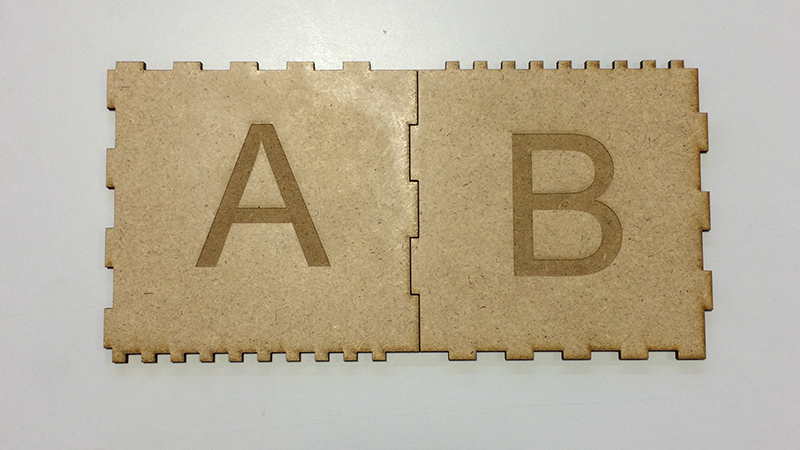

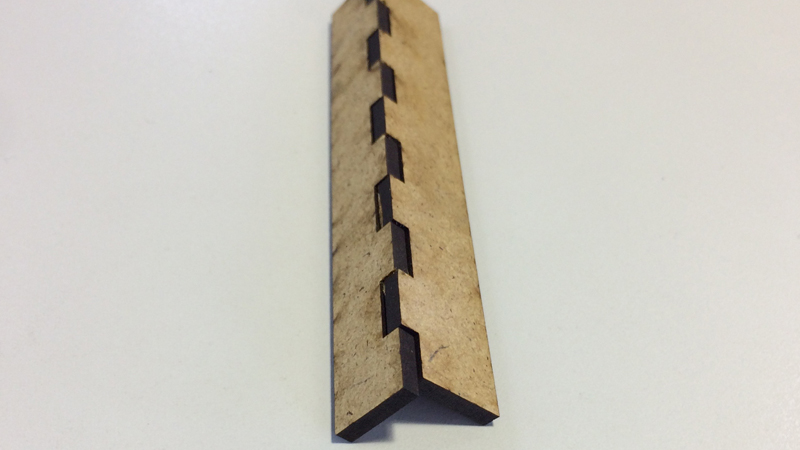

But before i draw the box i try various sizes fittings in test pieces.

But before i draw the box i try various sizes fittings in test pieces.

In my first test i draw two pieces to try the fittings, each side of the piece have different sizes.

After i chose the size of fittings, i test in a small piece the consistency of fitting i chose for my prototype.

After i chose the size of fittings, i test in a small piece the consistency of fitting i chose for my prototype.

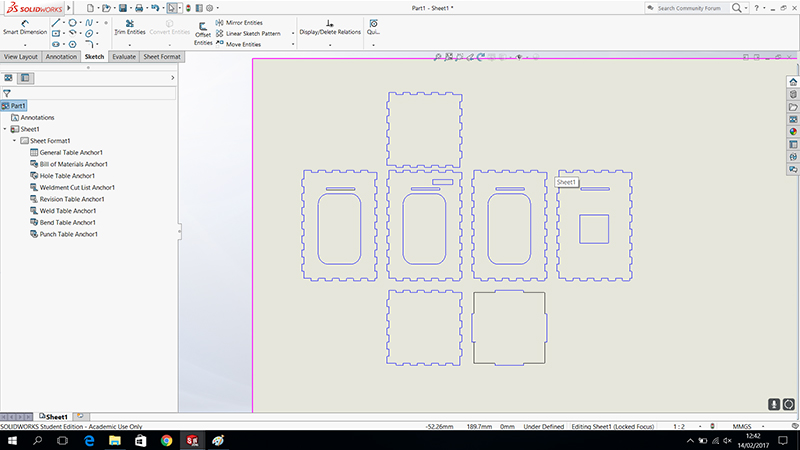

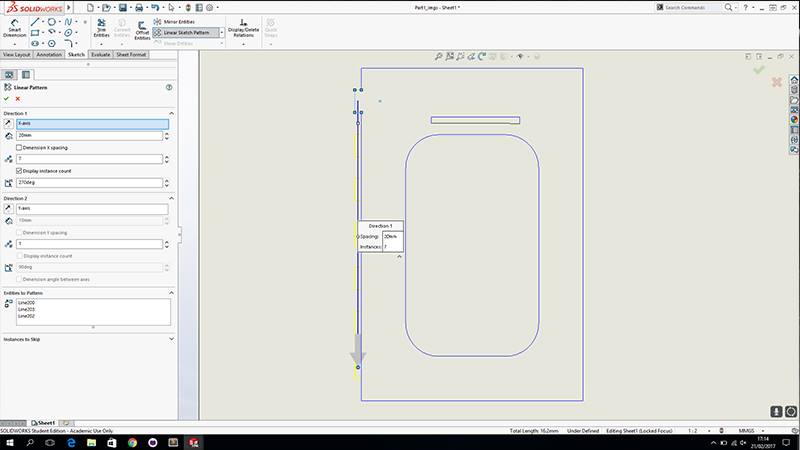

I make a parametric model in this way.

I draw the fittings with the corrects sizes and after i use the Linear Sketch Pattern and in this way i change the size of one and all changes the correct size.

In this image you can see one example a make one Linear Sketch Pattern for one side ande i make for all sides to make a parametric model.

I make a parametric model in this way.

I draw the fittings with the corrects sizes and after i use the Linear Sketch Pattern and in this way i change the size of one and all changes the correct size.

In this image you can see one example a make one Linear Sketch Pattern for one side ande i make for all sides to make a parametric model.

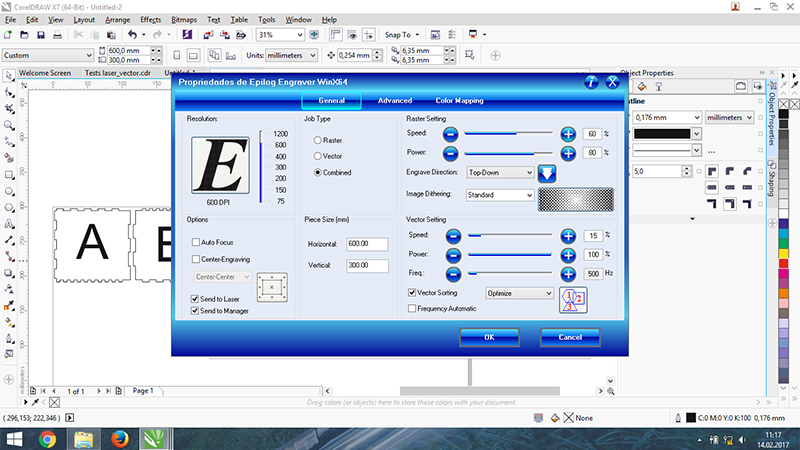

In Laser Cut we used the Corel Draw to send the cut file to Laser cut.

In Laser Cut we used the Corel Draw to send the cut file to Laser cut.

I used to make this tests MDF 0.3MM.

I used to make this tests MDF 0.3MM.

To use this material in Laser cut the parameters of cut are:

Speed: 15%

Power: 100%

Freq: 500Hz

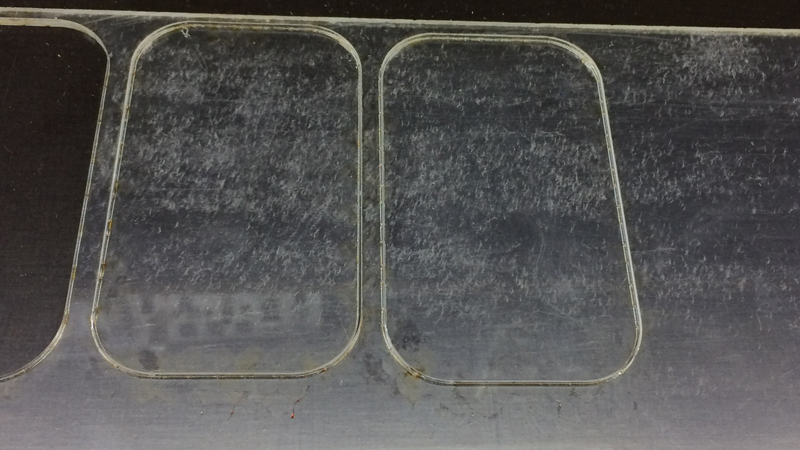

And i also used acrylic 0.3MM with this cut patameters:

And i also used acrylic 0.3MM with this cut patameters:

Speed:9%

Power:100%

Feq:5000 Hz

For make raster in my test piece i use this parameters:

For make raster in my test piece i use this parameters:

Speed:60

Power:60%

This is the final result of my small prototype.

Vinyl Cut

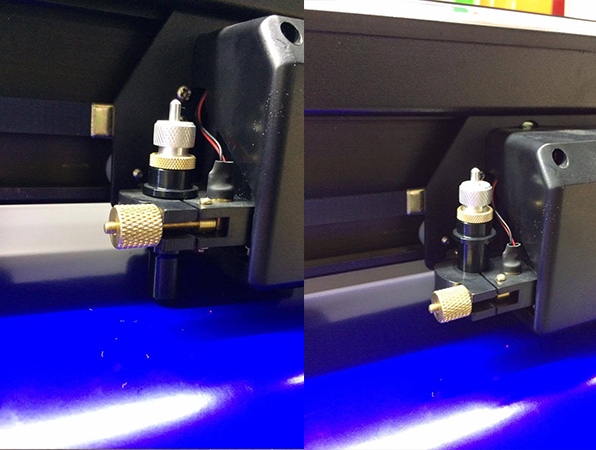

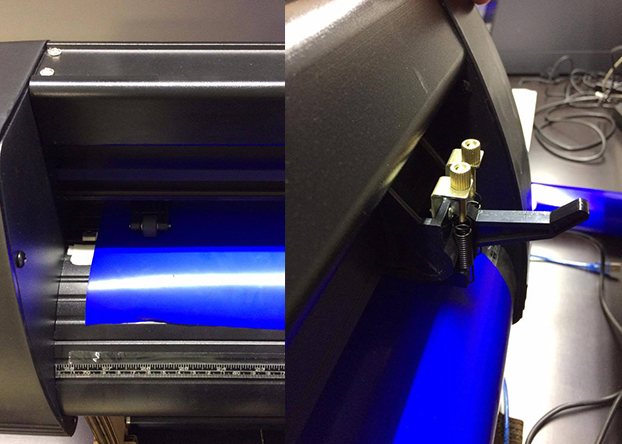

For the Vinyl cut i draw a small decorate vinyl to cut. I draw in solidworks and to send the file to the vinyl cut we use the inkscape with a plugin epilog. I use this vinyl cuter.

First i put the vinyl in the machine and hold the vinyl this way. This way the vinyl stay pressed an straight.

After i calibrate the lamina to cut right the vinyl.