Week no. 14

Composites :

- read the material safety data sheet (MSDS) and technical data sheet (TDS) for the resins that you're using design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it

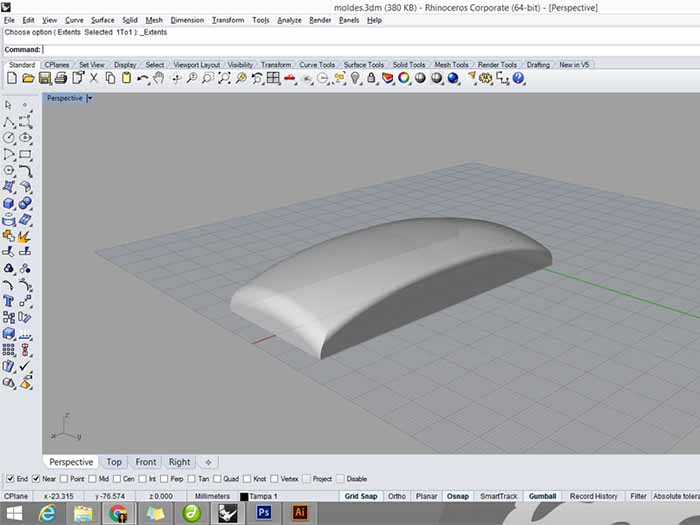

Design a 3D Mold

This week i thought i might would make and alternative for my previous cover for my brake ligh, but this time

with resin and fiberglass:

Started by designing the mold, for that i used Rhino:

Fabricate the 3D Mold

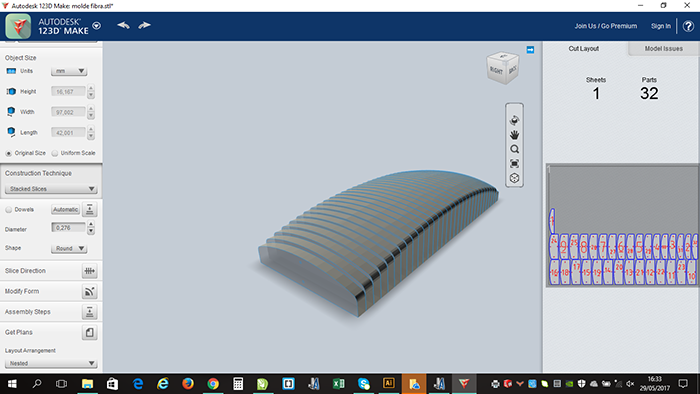

Then I exported the Rhino model to an stl file and imported the stl to Autodesk 123D Make:

After this i exported a pdf file with de model plans and

cutted it on the laser cuter machine and did the assemble:

Produce the Fiber Composite Part

Materials Used:

-

I used the CLR Epoxy Resin with the CLF Hardener, Resin and Hardner in 100:47 ratio.(Guide);

-

Peel ply and release film;

-

2 fiberglass layers;

-

Plywood mold;

-

Scale;

-

Vaccum bag.

First I started with a layer of release film and peel ply, next 2 layer of fiberglass and resin and another

ayer of release film and peel ply. After all the layers are piled, I used the vaccum bag with the vacuum pump:

I took the vaccum off after 24 hours, and this was the final result: