3_computer-controlled cutting

3_computer-controlled cutting

The matter of this week is related with Computer-Controlled Cutting.

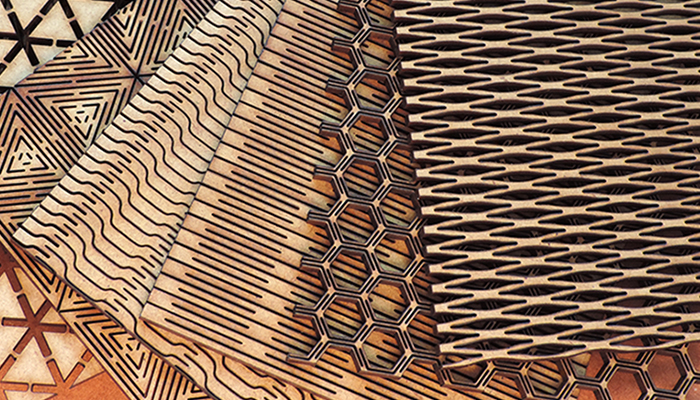

I think it is a powerful tool in order to build 3D models using 2D pieces. The process is not fairly direct and it requires interesting ways of approaching the issue.

Objectives:

-Cut something on the Vinyl-cutter

-Design, make, and document a parametric press-fit construction kit

VINYL-CUTTER

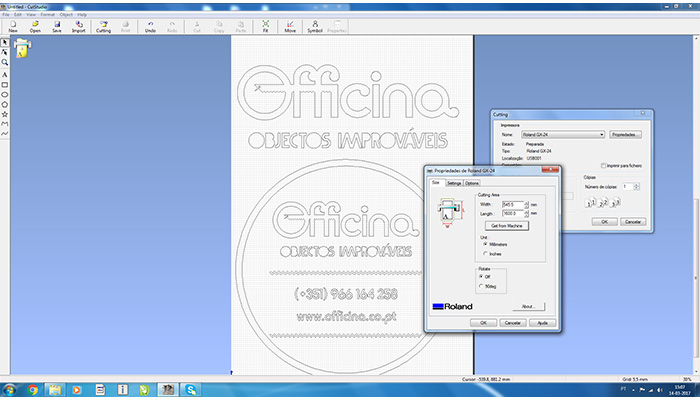

The first assignment for the week was to make something with the Vinyl Cutter Machine, I decided to cut my logo.

I used 2 programs for preparing the file, first I made the vector in Illustrator, but for some reason I couldn't open the file in the machine's program, it wasn't recognized in any of the formats I've tried.

How to MAKE it

At the FabLab Aldeias do Xisto we have a Roland G40

Process:

I used the Cutstudio to open the file from Illustrator in order to cut the black vinyl in the Roland cutter Machine

The production process

And I used gray vinyl, and the Roland Vinyl Cutter to make this task

The application process

And this is the final result!

The second project of the week was to design and prototype an object using laser cutting.

LASER CUTTING

This kind of matter are quite common for me and I feel comfortable enough with it.

How to MAKE it

At the FabLab Aldeias do Xisto we have a Spirit GLS 80Watt Laser. The machine has a work space of 900mm x 600mm.

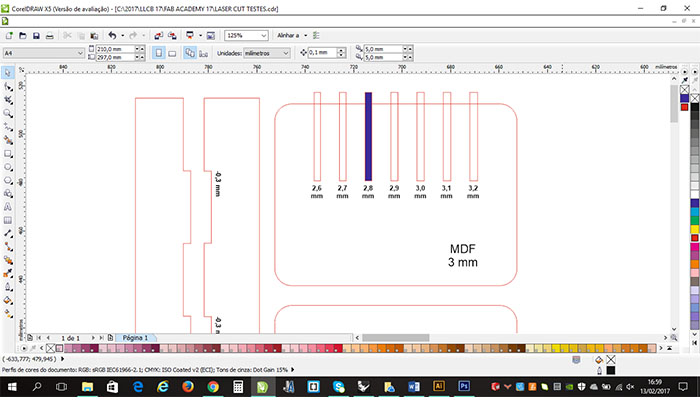

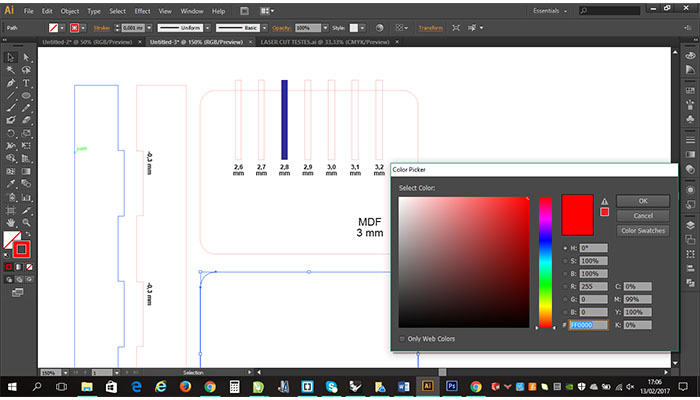

First step, test tolerance.

I made a press-fit test kit. I did it in Corel draw

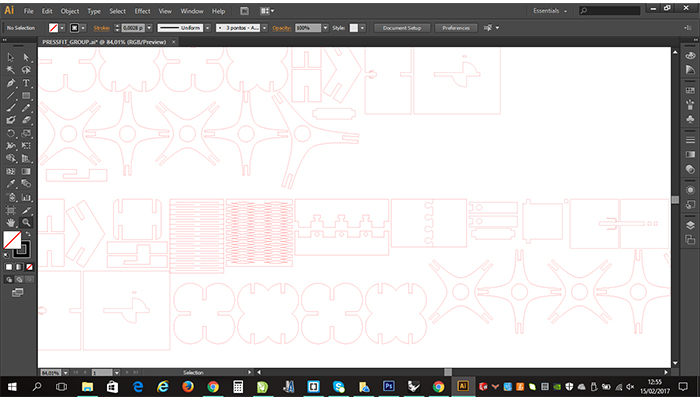

and Illustrator

Group Assignment

We started this assignment by searching some works done in pressfit, and we found some usefull links,did some tests and found a few pressfit pictures in the web that we started do draw in illustrator. We used 3mm plywood for this tests. We couldn't find good cardboard.

Drawing the group assignment

Lasercutting the pieces on our Spirit GLS

In the end, Each of us focused on one specific joint

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa

aaaaaaaaaaaaaaaaaaaaa