Week 3 - Press Fit Structures as Blown Glass Moulds Experiences - Part 3 Laser

Using the Laser Cutter for blown glass moulds

This experience is based in two premises:

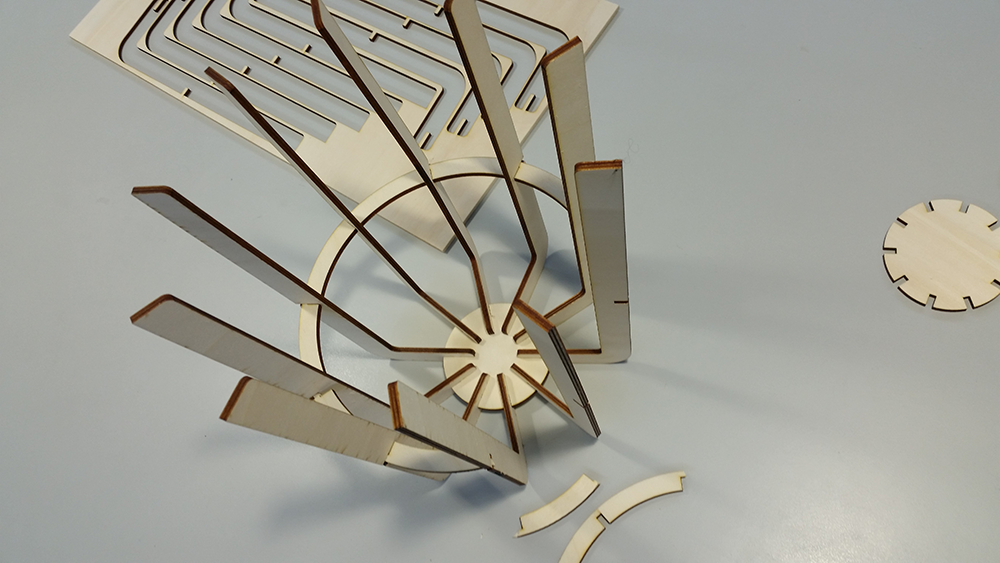

It is quite easy to produce relatively big structures using press-fit thin plywood laser cuts;

You can use wood for blown glass moulds. The wood has to be burned and soaked before usage.

I’m also very interested on exploring the dichotomy between precision and aleatory generative control on traditional and artisanal artifact production processes.

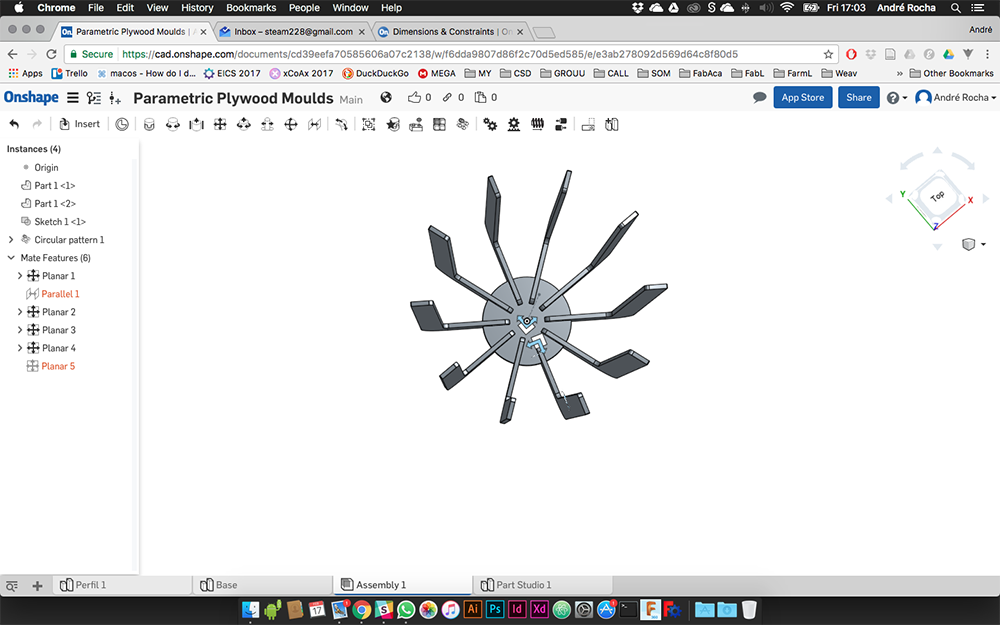

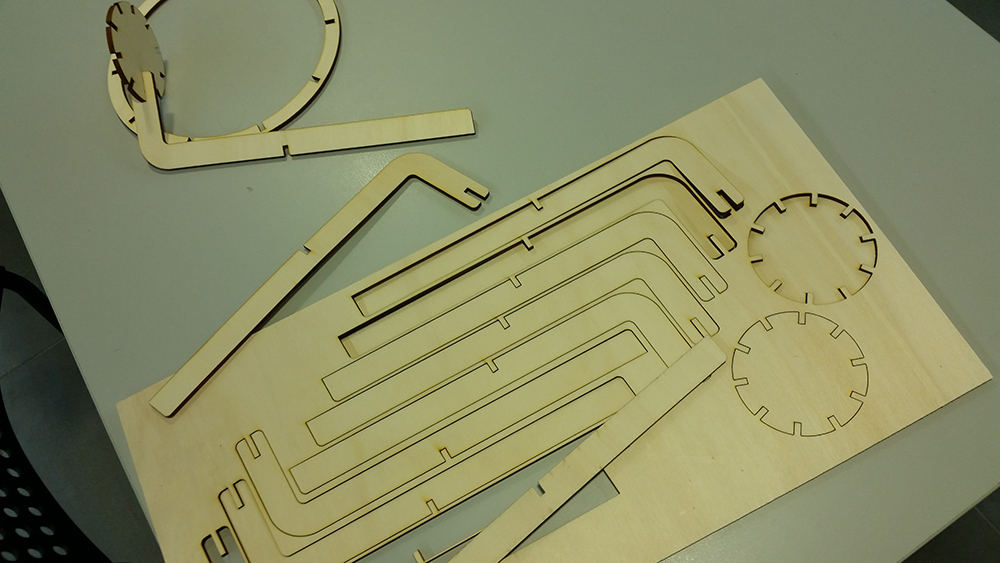

All these made me come up with this experience, where I used a 3D design, divided it into radial sections exporting those same sections to 2d designs for cuts. The design was tested on onshape. From there exported as drawing at 1:1 scale and opened it on illustrator, compiling all into a cut file.

Another interesting thing about this process is that the laser already burns the wood, and that it is essential to seal and soften the wood to make contact with the fusing glass.

In the end, I think I have a pretty nice process to repeat with a couple more designs, and turn it into a collection.

If by any chance you want to try or adapt the design, here is the cutting file.